Unfortunately all classic minis are prone to rust especially in certain areas. The only way to cure this problem is to cut out the effected area and weld in a repair section or new panel. After this has taken place rust proofing is essential.

We use latest and most sophisticated rust inhibiting primers . On the underside of the car either stone chip and body colour or 3M under seal is used. All cavities are painted using a rust proof primer, seam sealed and then injected with 3M anti-corrosion wax.

After painting, vulnerable exterior areas are coated with cavity wax for extra protection. All of these methods will help improve the longevity of your car. We fully recommend bring your car back annually for a weather proof check.

Example 1: Rear Wheel Arch Repair

The effected area is cleaned to reveal the extent of the corrosion. It is then cut well past this into good metal. Then a new section is butt welded in. Next the area is painted with a rust proof primer and seam sealer is used on any seams. Finally the area is under sealed for a lasting durable finish.

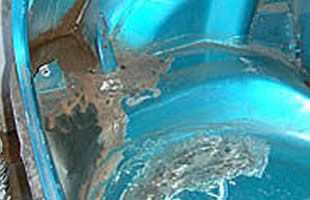

Example 2: Boot Floor Repair

In 99% of cases the boot floor, rear valance and valance closers are replaced at the same time. This involves cutting out the rear valance, closing panels and a section of the boot floor depending on the extent of the corrosion. In most cases the bottom lip of the rear panel will also have to be repaired. The small selection of pictures below shows this work being carried out.